NEXTBMS project

About NEXTBMS

The EU aims to become an economy with net-zero greenhouse gas emissions, achieving climate neutrality by 2050. Batteries will enable this clean energy transition by helping to decarbonise transport and enabling a higher uptake of renewable energy technologies. Therefore, the electrification of the European economy and society, both in transport and stationary storage sectors, has resulted in an expensive growth of the European battery industry (from battery cell manufacturers to recycling and second use companies). Achieving optimal utilisation of battery systems (by increasing the operational and lifetime usage window and reducing cost via a more efficient and appropriate use of materials) benefits not only the environment but also the end-users.

NEXTBMS will contribute to this by developing in the next 3,5 years an advanced battery management systems (BMS) built on fundamental knowledge and experience with the physicochemical processes of lithium-ion batteries. In this way, it will ensure that the next generation of BMSs will enable higher performance, safety, and longer lifetime of the battery cells for an overall optimal utilisation of the battery system.

Objectives

The core objective of NEXTBMS is to achieve a best-in-class advanced BMS hard- and software solution concerning technical performance, adaptiveness, and cost, for first life perspective as well as end-of-life (second life) management.

NEXTBMS will realise this by means of the following scientific and technical objectives:

TO1: Develop Advanced physics-based and adaptable battery models.

TO2: Deliver advanced data acquisition combining sensor-based solutions at battery system/module level and model generated values.

TO3: Integrate new control algorithms with advanced state estimators and data-based algorithms to increase utilisation while ensuring safety and reliability of the advanced BMS system.

Concept

The new BMS includes innovative and scalable physics-and data-based models, advanced HW, innovative sensors, and data-driven approaches.

The key elements of the concept are:

- Better understanding of cell chemistry and physics and incorporation of this knowledge in parameterised models by testing;

- Enhanced cell models that are physics-based and thus physiochemically consistent;

- Advanced data acquisition by battery sensors and measurement techniques that feed the models;

- Novel approaches, methods and control algorithms integrating from the software (SW) side the enhanced cell modelling and from the HW side the extra-cell new sensors and measurement techniques.

The developed BMS will be validated in transport and stationary application related load cycles (use cases) and will include strategies for optimal exploitation of on-board/off-board processing (interaction of the embedded BMS and the cloud). The enabling technologies will be matured from TRL 2 to TRL 4.

Approach

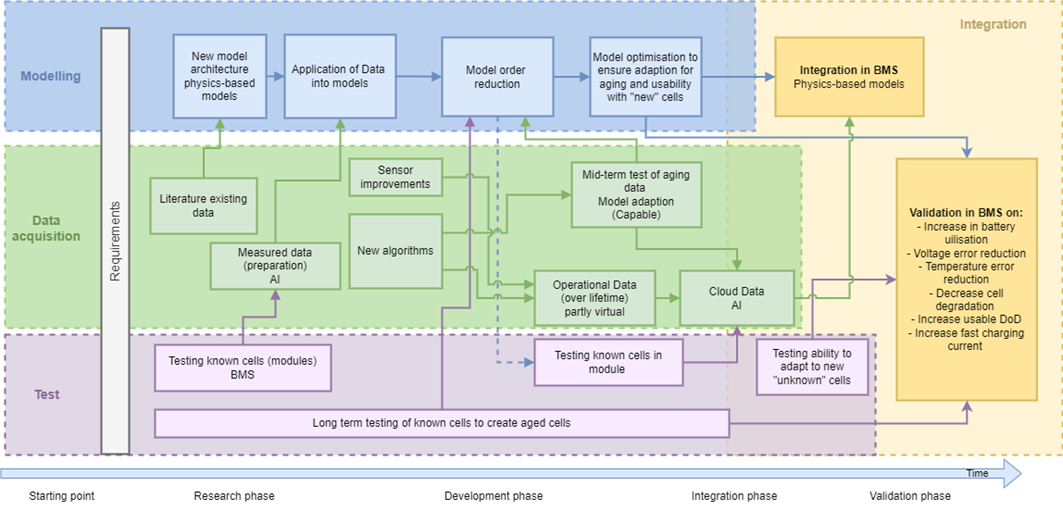

The pathways show a clear means of proceeding through the project with the necessary interaction between pathways when data is needed or results relevant for the next step. The core of the project revolves around the novel modelling (blue in figure below)). This is followed by the data acquisition (green in figure below) pathway that explains both the new HW sensor network and how AI will support the advanced data-based approach. The architecture for BMS integration (yellow in figure below) and the interaction between the embedded BMS and the cloud is then presented. This is followed by descriptions of how testing and validation will be tackled.

Structure

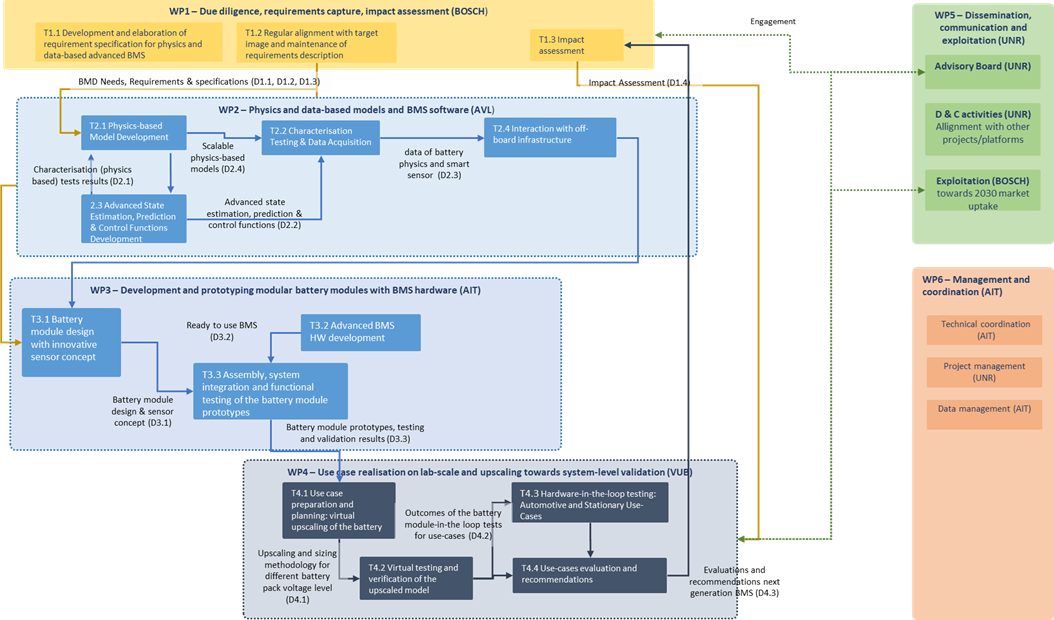

The NEXTBMS workplan is divided into:

- 4 research-related work packages

- 1 dissemination work package

- 1 management related work package

Results

System design with the development of models and sensors in parallel, giving better insight in the degradation processes inside battery cells (loss of active material, growth of unwanted material inside the battery, deposition of material on the anode, etc.).

NEXTBMS Expected Results:

- System design with the development of models and sensors in parallel, giving better insight in the degradation processes inside battery cells (loss of active material, growth of unwanted material inside the battery, deposition of material on the anode, etc.).

- Advanced physics-based model: physical model based on electrochemistry runs on BMS, powered by greater computing power. Which is combined with online models with artificial intelligence, based on a large database with lab and vehicle data, also from other vehicles.

- Measurement infrastructure for simultaneous multicell current and voltage measurement for EIS measurement, with specifications for an EIS chip, signal processing architecture to enable the spectral analysis and impedance evaluation.

- Analysis and extended knowledge by testing on cell-level (physicochemical, electrical, thermal and aging characterization) and module-level (electrical, thermal validation and functional validation).

- Quickly adaptable procedure with fast parameterisation for new battery material, chemistry, and configuration.

Facts and figures

Acronym: NEXTBMS

Duration: 42 months

Start date: 01-06-2023

Total budget: 4.998.318,25 €

EC Funding: 4.998.318,25 €

GA: 101103898

Publications

NEXTBMS is conducting research in the field of physics and data-based BMSs and will disseminate scientific results to peers in the field by means of scientific publications. All relevant publications will be posted on this website.